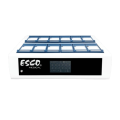

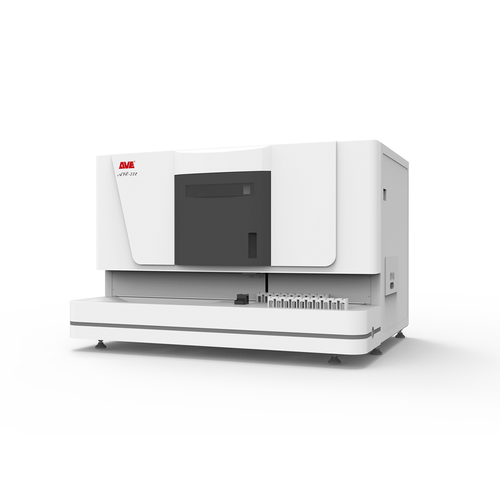

MIRI II-12 Multiroom Incubator

Shipped From Abroad

The Esco Medical MIRI® II-12 Multiroom Incubator is intended to be used to provide a stable culture environment at or near body temperature and CO2 and N2 gases for the development of gametes and embryos during In Vitro Fertilization (IVF) and Assisted Reproduction Technology (ART) treatments.

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

Description

MIRI II-12 Multiroom Incubator

To ensure maximum performance and an environment with the least amount of stress for embryos, the Esco MIRI® II-12 Multiroom Incubator dedicates one chamber for each patient and has 24 completely separate PID temperature controllers.

The chambers are separate from one another and do not affect each other’s temperatures in any way. There is no effect on the remainder of the system from any disruption in one chamber, such as a temperature reduction after opening the lid. The temperature in the culture chambers and the lids can be controlled and regulated as well. The top and the bottom of each chamber are separated with a PET layer so that the lid temperature would not affect the bottom.

For validation purposes, each compartment has a PT-1000 sensor built in. The circuitry is separated from the unit’s electronics, so it remains a truly separate validation system.

The incubator needs 100% CO2 and 100% N2 to control the CO2 and O2 concentrations in the culture chambers. A dual-beam infra-red CO2 sensor with extremely low drift rates controls the CO2 levels. On the other hand, a chemical, medical-grade oxygen sensor controls the levels of O2 in the system.

CO2 recovery takes an average of 3 minutes after opening the lid.* The MIRI® II-12 incubator is fitted with 12 gas sample ports that allow the user to validate gas concentration by sampling gas from the individual compartment.

The incubator also features a recirculated gas system where gas is continuously put into the compartment and taken out at the same rate. Gas is cleaned via a 254 nm UVC light with direct gas contact between the bulb and gas. The UVC light has filters that inhibit any 185 nm radiation that would produce dangerous ozone. The filters are located under the UVC light. The complete gas repletion in the system takes less than 5 minutes.

- Pressure regulator (preventing dangerous gas pressure problems)

- Gas flow sensors (actual consumption can be accumulated)

- Gas pressure sensors (allow the user to know the pressure, and the variation can be logged to avoid dangerous conditions)

- Gas filters (to prevent valve problems)

Features

Heated Lid

Prevents condensation, enhances consistency throughout each chamber, and improves temperature regulation and recovery.

Heated Bottom

Allows for reliable temperature regulation by providing direct heat transfer to the culture dishes.

Fast Recovery

The quick recovery of temperature and gas characteristics after opening a chamber is a significant advantage when utilizing the MIRI® II-12 multiroom incubator.

Stress-free Validation of Chamber Parameters

For gas and temperature validation, the MIRI® II-12 can be connected to an external device such as the Esco MIRI® GA. The primary circuitry is fully separate from the built-in PT1000 temperature sensors. Additionally, all 6 or 12 chambers have gas sampling ports.

Intuitive Touchscreen Controls

User-Friendly and Full-Featured Data Logging System

One computer can control and connect to multiple machines. The machine’s real-time parameters can all be simply viewed in the MIRI® II-12’s built-in touchscreen PC. These parameters include every temperature and gas concentration point, as well as the set points for all gas input pressures and flow rates. Graphs are also available for viewing that show all machine performance information, including alerts, which are continuously documented. Weekly reports are also generated automatically by the data logger, making it more user-friendly.

Heating Optimization Plates

A heating optimization plate is included in each chamber to help heat transfer directly to the culture dishes. Each chamber contains inserts that suit different-sized dishes.

Specifications

| Overall dimensions (W x D x H) | 740 x 575 x 215 mm (29.1 x 22.6 x 8.5”) |

| Net Weight | 47 kg (99.2 lbs) |

| Material | Mild steel / Aluminum / PET / Stainless steel |

| Power supply | 115V 60Hz or 230V 50Hz |

| Power consumption | 500W |

| Temperature Control Range | 25.0 – 40.0 °C |

| *CO2 Gas Consumption | < 2 liters per hour |

| **N2 Gas Consumption | < 12 liters per hour |

| CO2 Control Range | 3.0% – 10.0% |

| O2 Control Range | 5.0% – 10.0% |

| Gas Input Pressure | 0.4 – 0.6 bar (5.80 – 8.70 PSI) |

| Operating Altitude | Up to 2000 meters (6560 feet or 80kPa – 106kPa) |

| Shipping weight | 57 kg (121.3 lbs) (Including the pallet’s weight) |

| Shipping dimension | 890 x 710 x 480 mm (35 x 28 x 18.9”) (device on the pallet) |

Reviews

There are no reviews yet.